The Research— 997 Intake Manifold Valve Development

After my 997 GT3 RS engine failure at Area 27, I needed answers — not just about what failed, but why it failed.

Specifically:

Why does this intake manifold even contain valves? And what’s the failure history behind it?

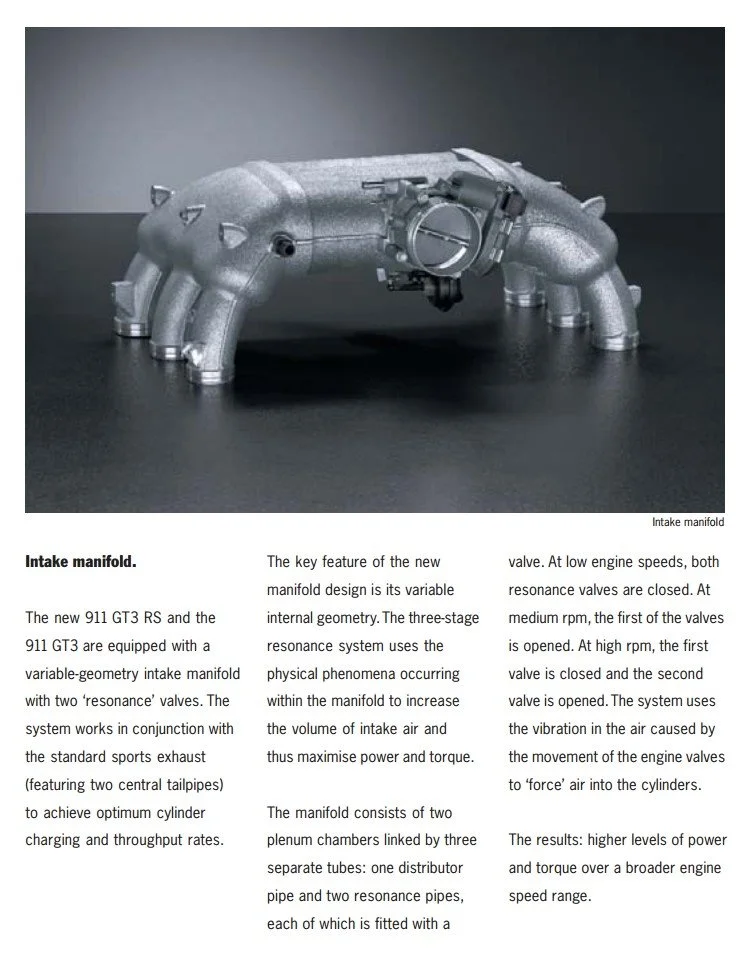

Turns out, Porsche was proud of this system — it was part of the original marketing material for the 997.2 GT3 RS:

The manifold consists of two plenum chambers linked by three separate tubes: one distributor pipe and two resonance pipes, each of which is fitted with a Intake manifold valve. At low engine speeds, both resonance valves are closed. At medium rpm, the first of the valves is opened. At high rpm, the first valve is closed and the second valve is opened. The system uses the vibration in the air caused by the movement of the engine valves to 'force' air into the cylinders.

The results: higher levels of power and torque over a broader engine speed range.

GT3 RS 3.8 Marketing Material

A Clever System With a Fragile Design

This dynamic intake concept is great in theory — improving power delivery across the rev range.

But as more cars reach high mileage or consistent track use, mechanical failures inside this system are emerging.

So I dug deeper: Was mine a rare case? Or a known issue?

The WC512 Campaign: An Early Warning Sign from Porsche

In 2013, Porsche issued a workshop campaign — code WC512 — that targeted a failure inside the intake resonance system of the:

997 GT3 RS 3.8

997 GT3 RS 4.0

The problem?

Screws within the resonance valve assembly could loosen over time, fall into the intake path, and be ingested by the engine — with destructive results.

The WC512 fix involved replacing the resonance tube with a revised part. It wasn’t a recall, but rather a preventive campaign offered during dealer visits. Naturally, I checked whether my car had received it. I called my Porsche dealer, and they confirmed:

“Your VIN had WC512 completed in November 2013.”

So the fix had been applied. Yet my engine still failed — not from loose fasteners, but from a different flaw entirely.

More Cases Appear — Same Mode of Failure

I started reading through threads on Rennlist — and found several documented cases of near-identical failures on other 997 GT3 RS cars. See the thread below.

I'd like to focus on Rennlist user Ilko’s failure, as it has good amount of documentation behind it.

Failure #1: Ilko’s GT3 RS

Rod snapped inside the intake manifold.

Fragments were found embedded inside the engine.

Breaks appeared at the same stress points as mine.

Due to Higher RPM, failure causes significantly more damage to the head and piston.

Failure #2: My GT3 RS

Rod broke in two places: externally near the linkage, and internally where it rides in the bushing.

One chunk was located resting on top of a piston — discovered during teardown.

Both cases shared the same characteristics:

Clean fatigue fractures through the shaft.

Fragmentation inside the manifold.

Portion of the rod sucked into the combustion chamber.

Conclusion: This Is a Predictable, Fatigue-Based Failure

This isn’t anecdotal. It’s a repeatable failure caused by:

Poor rod design with stress concentrators

Use of lower-grade carbon steel (Steel 1040)

Thin cross-section prone to fatigue cycling under resonance loading

Even cars with the WC512 campaign completed are still vulnerable — because the fix didn’t address the root cause: poor rod design.

In the next post, I’ll cover the development of a new intake manifold valve I am willing to test on my own 3.8 Mezger motor.